ROVs for Nuclear Cooling Pond Inspections: Safety Meets Precision

Exploring how Remotely Operated Vehicles (ROVs) enable safe, efficient, and non-invasive inspections of nuclear cooling ponds—where traditional methods fall short.

When we think of nuclear safety, most people picture thick containment domes and heavy shielding. But some of the most crucial components of a nuclear facility lie underwater—in the form of cooling ponds. These ponds store spent fuel rods, submerged in large volumes of water that act as both a coolant and a radiation shield.

And when it’s time to inspect these critical structures, there’s one obvious problem: no human can dive in.

That’s where Remotely Operated Vehicles (ROVs) become indispensable.

The Problem with Cooling Pond Inspections

Nuclear cooling ponds are typically 10 to 15 meters deep and densely packed with high-radiation fuel assemblies. Inspections are necessary to:

- Check the condition of underwater infrastructure (walls, racks, fuel storage trays)

- Monitor sediment buildup or debris

- Detect leaks or potential structural weaknesses

- Ensure cooling systems and flow patterns remain unobstructed

Traditional methods for inspection involve long-handled tools, underwater cameras on booms, or draining the pond entirely—all of which come with high risk, cost, and complexity. Not to mention radiation exposure concerns and extended downtime for the facility.

ROVs: The Safer, Smarter Alternative

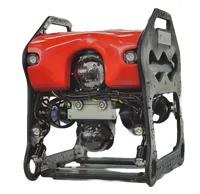

ROVs solve this elegantly. Compact, remotely controlled, and equipped with high-resolution cameras and LED lights, these underwater robots can navigate the murky, confined waters of cooling ponds without ever exposing a human to risk.

Why ROVs Make Sense for Nuclear Environments:

- Radiation Safety: No human entry required in high-radiation zones

- No Downtime: Ponds remain operational during inspection

- Non-Invasive: Zero disturbance to sediment or fuel assemblies

- Data-Rich: Capture detailed video logs and high-res images for documentation

- Precision Control: Manoeuvrability even in tight grid structures or around racks

Specialized Payloads & Features

Nuclear environments are unique, and so are the ROVs that operate in them. Some of the enhancements EyeROV systems offer for such missions:

- Radiation-hardened electronics

- High-intensity LED lighting for low-visibility operation

- Laser scaling modules to measure cracks, gaps or deformations

- Sonar payloads for turbid environments

- Manipulator arms for sample collection or obstruction removal

EyeROV in Action

At EyeROV, we’ve tailored inspection solutions for high-stakes environments like nuclear cooling ponds. Our ROV platforms, such as EyeROV TUNA, are equipped to handle the challenges posed by:

- Restricted access points

- Zero-tolerance safety zones

- High water conductivity and temperature

- Need for precise navigation inside dense fuel grid configurations

Our EVAP (EyeROV Visualisation & Analytics Platform) enhances the inspection process by offering timeline-based video analysis, annotation tools, and defect tracking over time—perfect for regulatory audits and long-term condition monitoring.

A Glimpse Into the Future

With nuclear energy playing a pivotal role in clean energy transitions globally, the safety and longevity of these facilities will only gain more importance. ROVs are not just replacing risky human operations—they’re elevating the quality, frequency, and value of inspections.

And as we continue to advance autonomy, AI-assisted defect detection, and cloud-based analytics, the bar for nuclear safety and maintenance will keep rising.

At EyeROV, we’re committed to designing underwater solutions that thrive even in the most sensitive environments. If your facility demands zero-compromise inspection standards—let’s talk.