Offshore Rig Inspection using Remotely Operated Vehicle

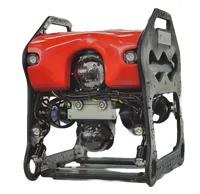

How EyeROV’s TUNA ROV enabled a high-quality underwater inspection of a deep water offshore rig under harsh marine conditions.

Case Study: Offshore Rig Inspection using Remotely Operated Vehicle (ROV)

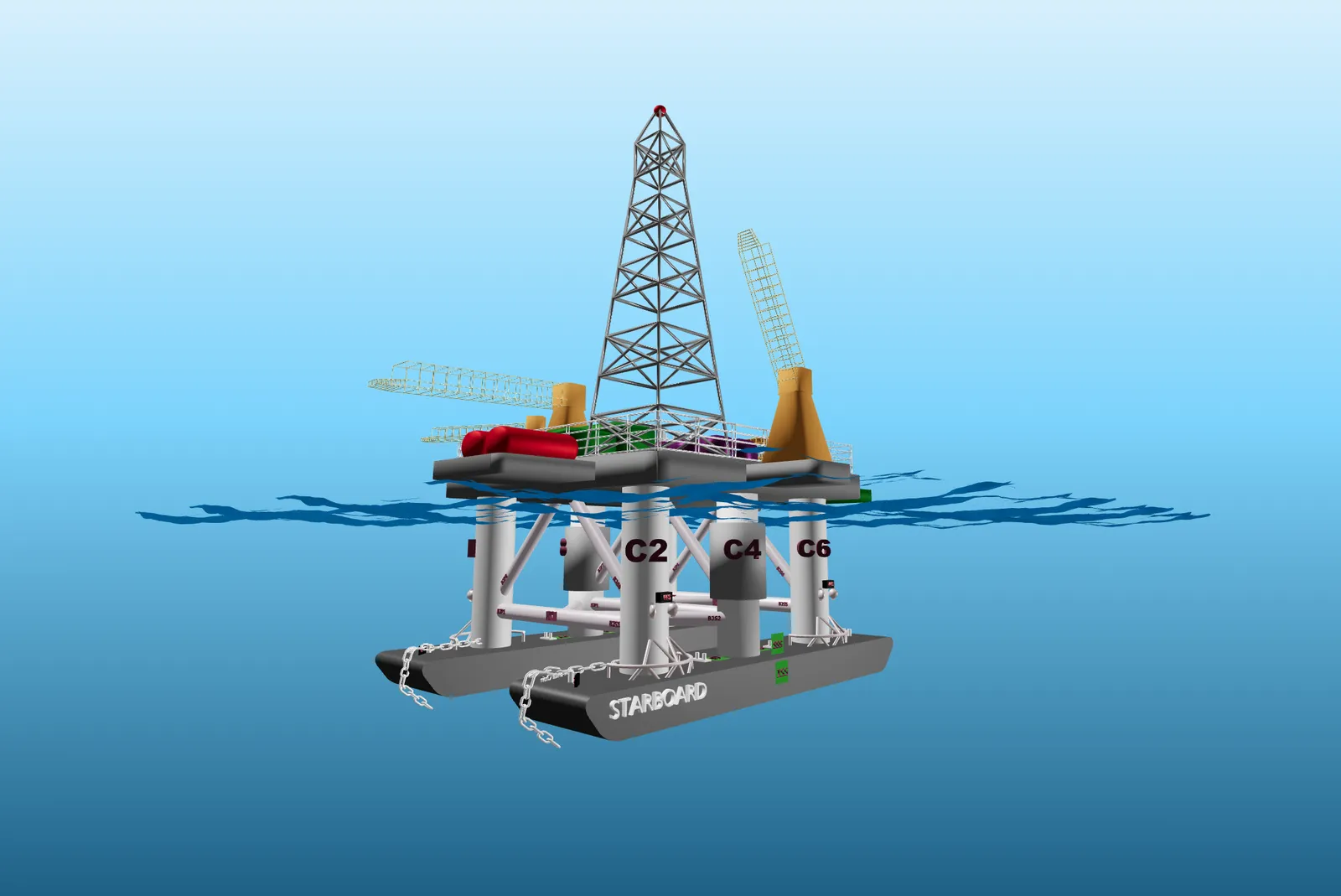

Offshore oil rigs are colossal, floating cities that play a vital role in global energy production. With structures like pontoons, sea chests, bracings, and K-joints, these rigs must endure harsh marine conditions — making routine inspection essential for safety, longevity, and operational efficiency.

While diver-based inspections are traditional, they pose considerable risk due to underwater hazards, poor visibility, and unpredictable weather. This is where ROVs step in. EyeROV’s TUNA ROV, designed for demanding underwater infrastructure monitoring, was deployed for a detailed inspection of a deepwater offshore rig.

Why ROV over Divers?

- Operates in challenging conditions (high current, low visibility)

- Removes the risk to human life

- Enables real-time high-definition visuals at various depths

Scope of the Inspection

EyeROV’s mission focused on submerged structural areas such as:

- Column-to-pontoon and column-to-bracing connections

- K-joints and sea chest gratings

- Tow bridle chains, fairleads, and bollards

- Diesel tanks and overall fly-by visual footage

These areas were examined systematically, with close-up footage recorded section-wise based on a predefined path plan.

Execution Highlights

The control station was set up onboard the rig. After manual launch from the deck, the ROV pilot navigated the vehicle in real-time while capturing high-quality visuals. The entire feed was streamed live to the onboard team, enabling immediate insight into the rig’s structural health. EyeROV engineers also trained the rig’s personnel in effective planning and coordination for ROV operations.

Results

- HD footage of all submerged rig components

- Consolidated findings delivered via hardcopy and a software platform

- 3D digital model highlighting inspected areas

Conclusion

The survey identified heavy marine growth across submerged rig parts. These findings underscore the importance of periodic inspections to reduce operational risks and ensure environmental safety. ROV-based inspection proves to be a reliable, safe, and efficient method to maintain offshore infrastructure and safeguard critical assets.

Read more about EyeROV’s Offshore Inspections.