Advanced Inspection Methods for Submerged Underwater Tunnels Using ROVs

Discover how cutting-edge ROV technology enables detailed, safe, and efficient inspections of submerged underwater tunnels, ensuring their long-term structural integrity.

Tunnels are engineering marvels — demanding to design, challenging to construct, and even harder to maintain. When these tunnels are submerged underwater, inspections and upkeep become even more complex and risky. For decades, submerged tunnels in hydropower dams, water diversion systems, and aqueducts were often left unseen after being flooded and commissioned, relying solely on robust design and safety factors.

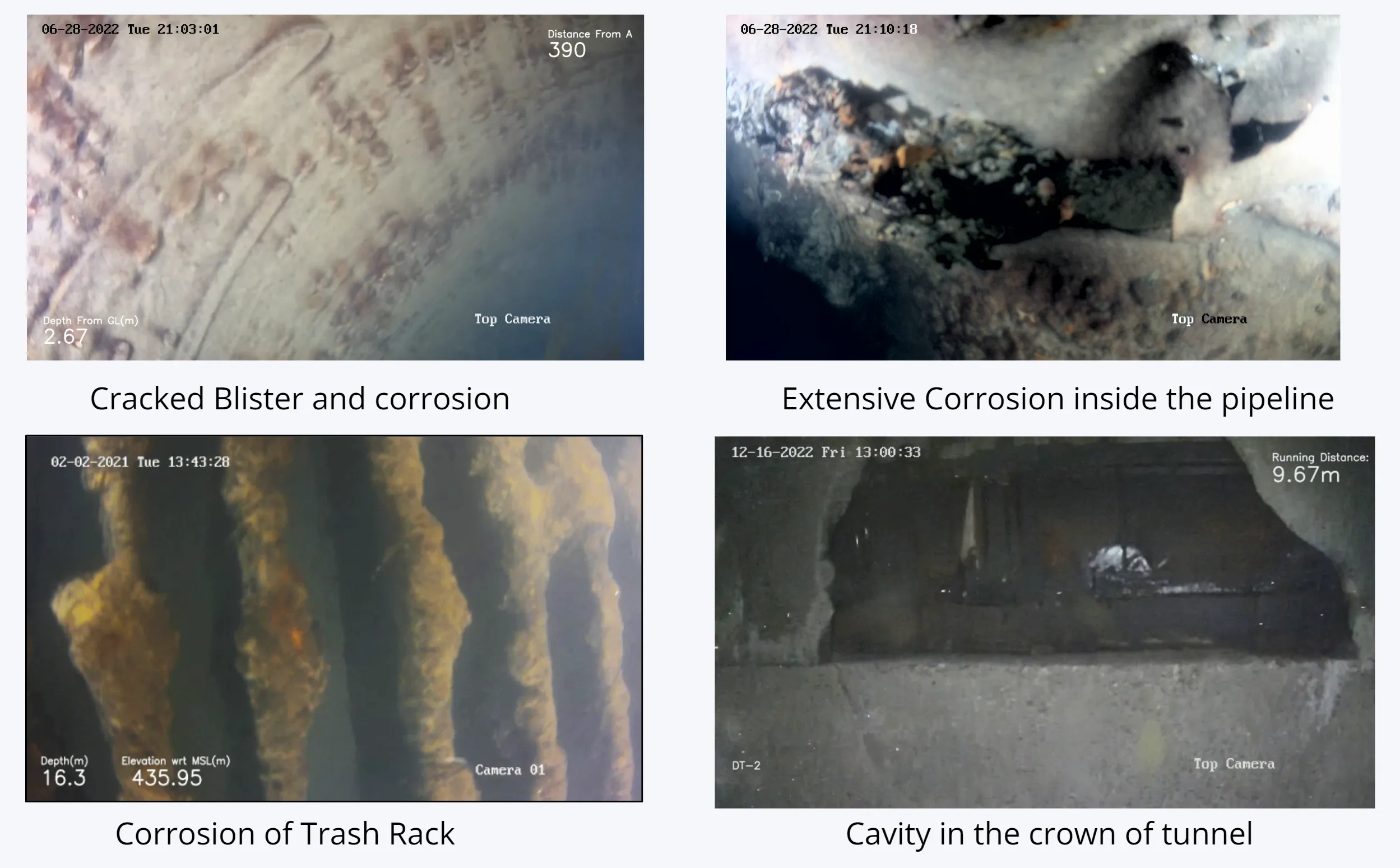

However, submerged tunnels are continuously subjected to hydrostatic and thermal stresses, which can compromise their structural integrity over time. Without timely inspections, these critical infrastructures face the risk of catastrophic failure, leading to extensive financial and even human losses.

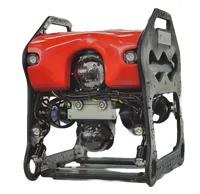

Today, thanks to Remotely Operated Vehicles (ROVs) like EyeROV TUNA, advanced tunnel inspections are not just possible but highly efficient and effective.

Challenges of Submerged Tunnel Inspections

Historically, inspecting submerged tunnels required dewatering — a costly, time-consuming process that interrupts operations and induces additional stresses on tunnel linings. Without inspections, issues like structural deformation, rock falls, sediment build-up, and lining separations could go undetected until it was too late.

The need for a safer, quicker, and more detailed inspection method has made underwater ROVs an essential tool for maintaining the longevity and safety of submerged tunnel infrastructure.

EyeROV TUNA: Revolutionizing Tunnel Inspections

EyeROV TUNA, a compact Observation Class ROV, is purpose-built for operating in submerged and flooded environments without the need to empty tunnels. Its advanced technology and rugged design allow it to perform comprehensive inspections with minimal operational downtime.

Recently, the EyeROV TUNA completed an impressive inspection of a 4 km-long tunnel at a major hydropower facility in Central India. Here’s how it achieved this:

- Extended Endurance: Extra battery modules multiplied operational time fivefold, critical for completing inspections within tight shutdown windows.

- Fiber Optic Tether: A specialized tether enabled uninterrupted communication and data transfer over long distances, handling tunnels exceeding 5 km in length.

- Customized Deployment: Each entry into the tunnel required navigating 40-50 meter deep vertical shafts, with careful planning to manage tether routing and ROV handling.

- Minimal Disruption: The inspection was conducted systematically to meet strict shutdown timeframes without affecting electricity generation or water supply.

Advanced Payloads for Comprehensive Assessment

EyeROV TUNA was equipped with a powerful suite of visual and non-contact inspection tools, including:

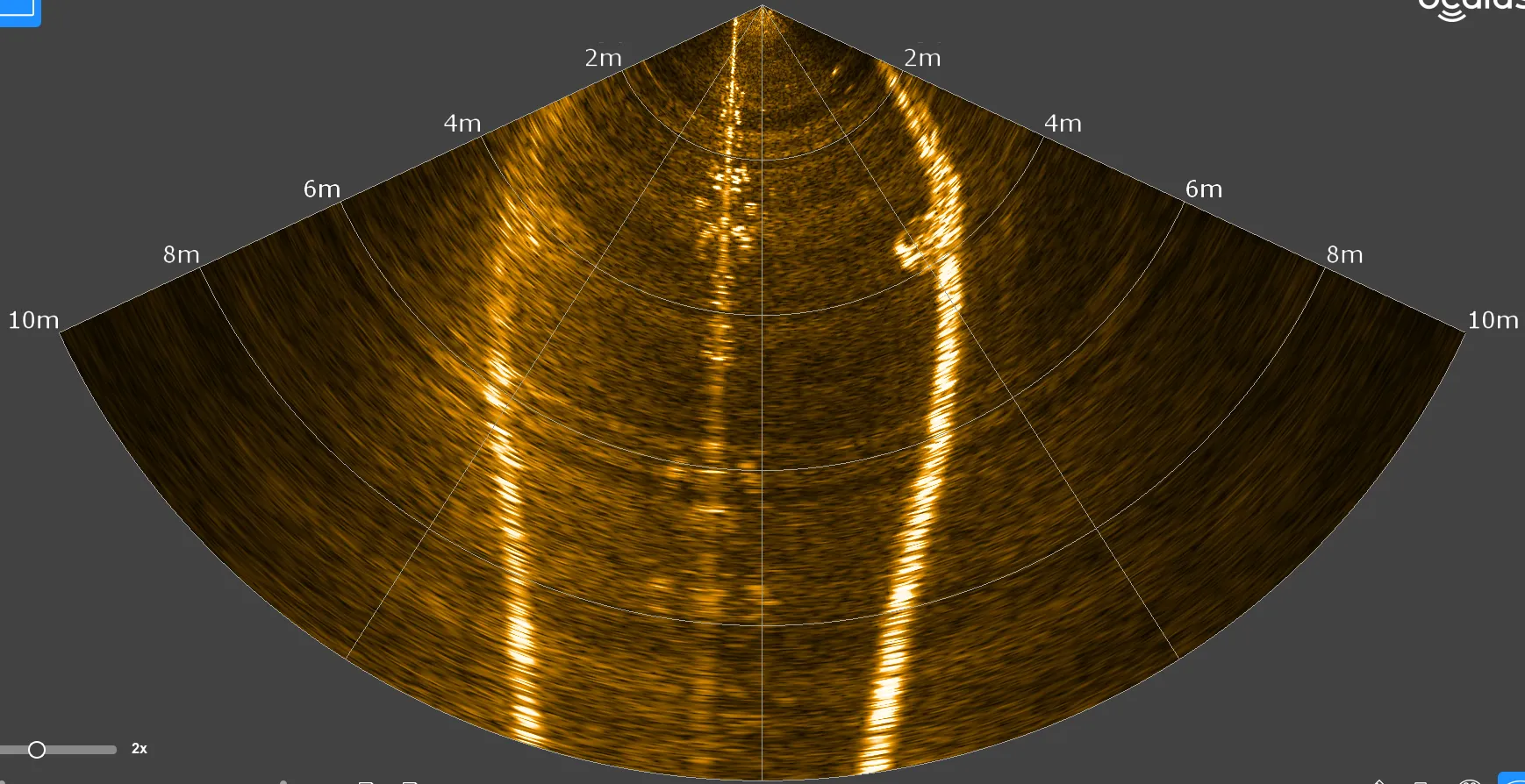

Imaging SONAR

Provides real-time sonar visuals even in zero-visibility conditions, crucial for safe navigation and identifying obstacles like rock debris and silt deposits.

Profiling SONAR

Captures precise cross-sectional profiles of tunnels, enabling the generation of 3D tunnel models for assessing deformation, displacement, and structural anomalies.

Laser Scalar

A laser-based measurement tool that accurately estimates defect sizes, allowing engineers to prioritize necessary repairs.

HD Cameras and High-Intensity Lighting

Delivers crystal-clear video footage in pitch-black environments, live-streamed to surface control stations for real-time monitoring and documentation.

High-Accuracy Navigation and Positioning

The system provides geo-referenced data with sub-meter accuracy, significantly reducing the time needed for fault identification and repair planning.

Methodology and Execution

The inspection was carefully planned to optimize efficiency and ensure thorough coverage:

- Entry Planning: ROV deployment from multiple vertical shafts with special tether management.

- Navigation: SONAR imagery and precise piloting enabled safe passage through long tunnel sections.

- Data Collection: Continuous capture of visual, SONAR, and laser data for comprehensive post-processing.

- 3D Modeling: Post-survey processing generated detailed 3D tunnel maps, highlighting cracks, separations, and sediment accumulations.

Key Outcomes

- Reliable Assessment: Identified and categorized defects, sediment build-ups, and structural deformations.

- Actionable Insights: Enabled targeted, cost-effective maintenance planning rather than unnecessary full repairs.

- Minimized Risks: Inspections without dewatering avoided additional stresses and extended tunnel life.

- Financial Savings: Reduced unplanned maintenance and operational disruptions.

By combining advanced ROV technology with expert execution, tunnel inspections are no longer a monumental challenge. Instead, they are a proactive strategy for ensuring the safety, functionality, and longevity of critical underwater infrastructure.

EyeROV’s cutting-edge solutions, including the TUNA ROV, are paving the way for safer, smarter, and more sustainable tunnel management practices.

Learn More about EyeROV’s Tunnel Inspections.