Ultrasonic Testing of Ship Hull with ROV

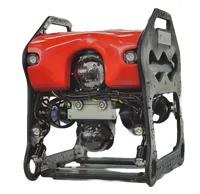

How EyeROV’s TUNA ROV performed underwater ultrasonic testing and visual inspection of a vessel’s hull, sea chests, and jet propulsion units.

Case Study: Ultrasonic Testing (UT) Inspection of Ship Hull using ROV

Ultrasonic Testing (UT) with Remotely Operated Vehicles (ROVs) is transforming how ship hulls and underwater assets are inspected. This non-destructive technique uses high-frequency sound waves to determine material thickness and detect internal flaws, ensuring structural health without dismantling any part of the vessel.

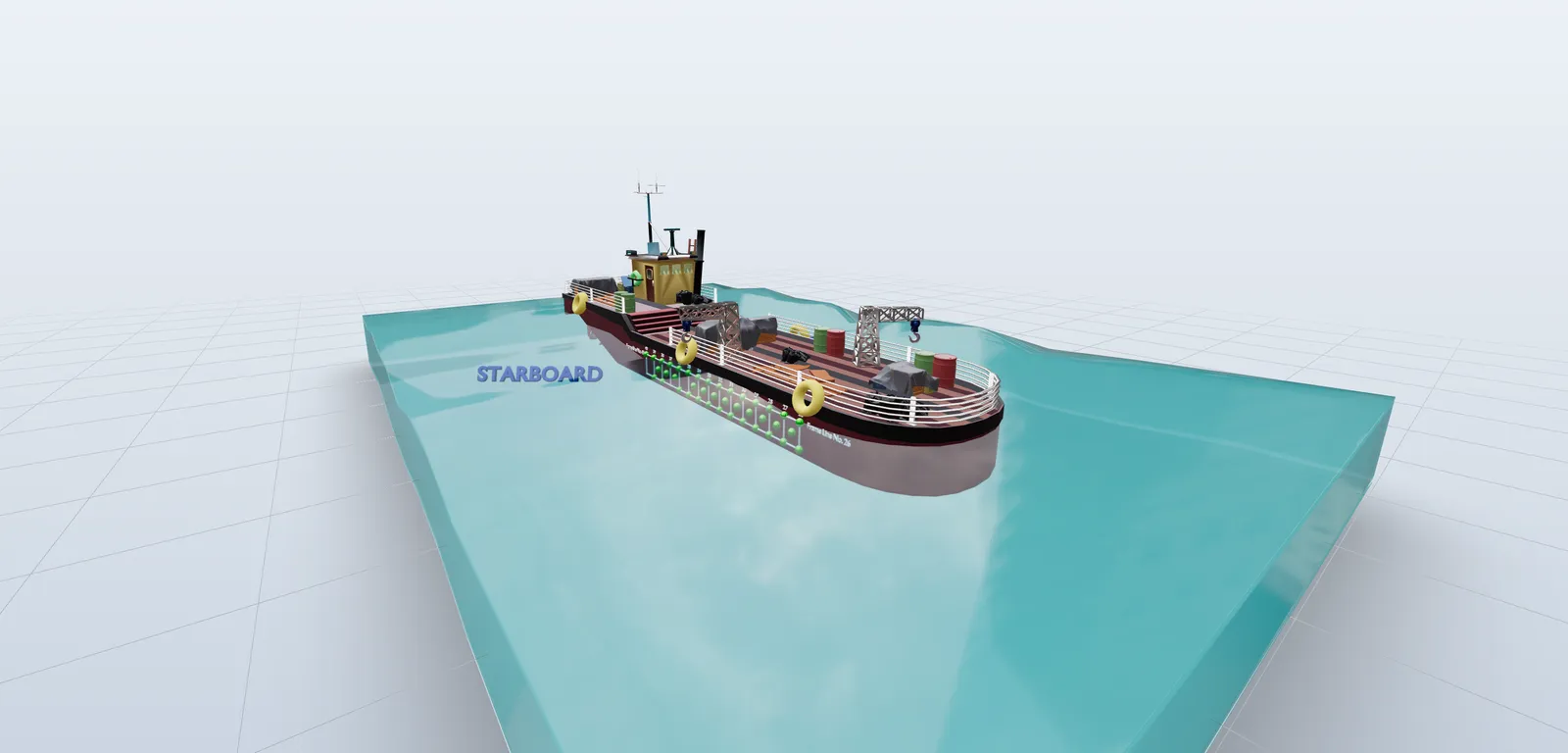

EyeROV deployed its TUNA ROV to carry out a detailed UT inspection on a ship’s hull. The operation involved mounting a UT probe on the ROV to capture precise thickness data and visual footage. The ROV was manually launched from a jetty-side control station and maneuvered close to the hull where both HD visuals and UT data were gathered.

What Was Inspected?

- Hull plates at selected locations

- 3 sea chests

- 2 jet propulsion units

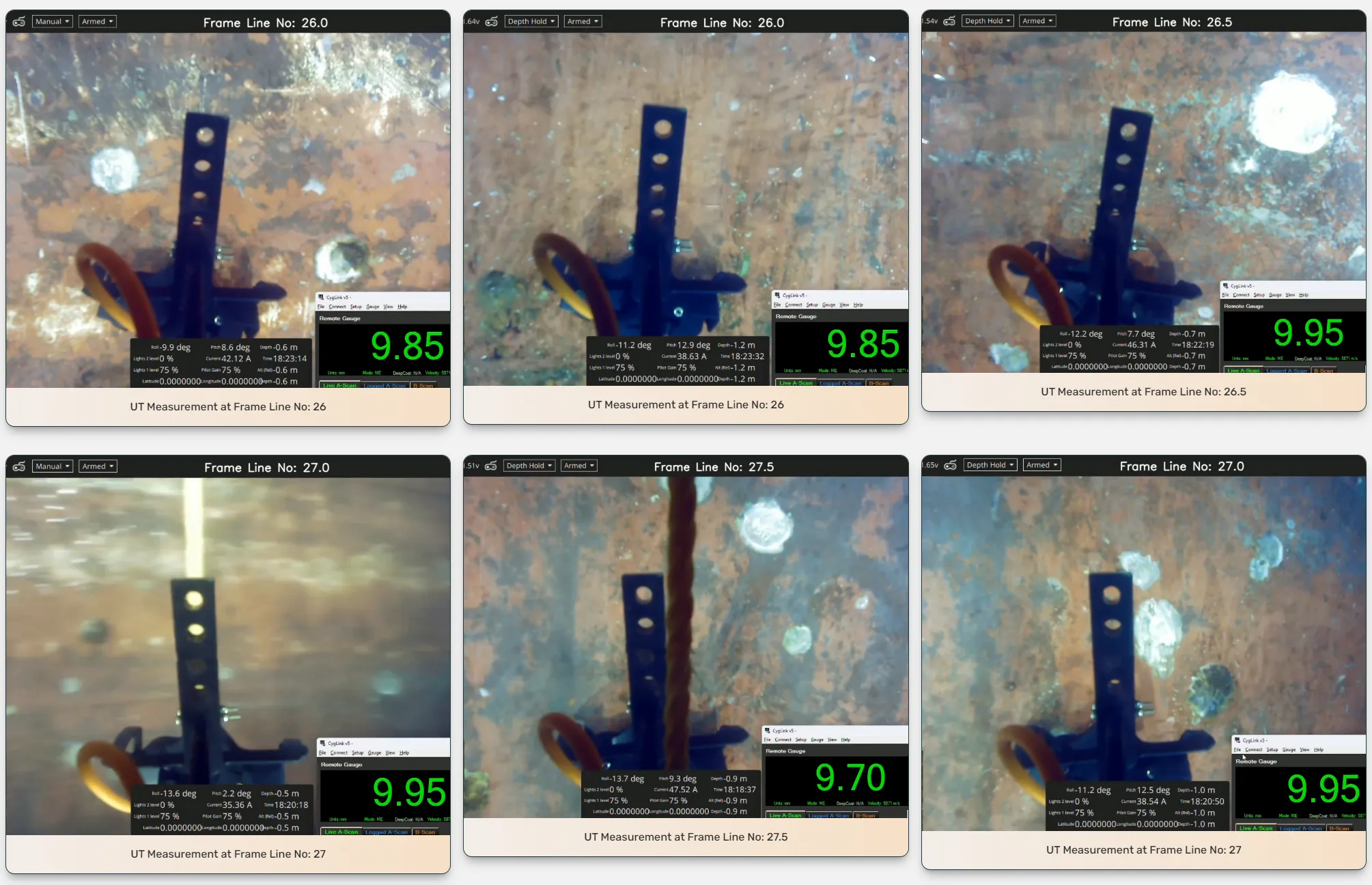

The UT probe delivered measurement resolutions up to 1/100th of a millimeter, ensuring accurate detection of corrosion or defects. Simultaneously, the visual inspection helped identify marine growth in the sea chest gratings and around the jet propulsion outlets.

Results

- High-resolution visuals of underwater components

- UT measurements confirmed consistent plate thickness

- No signs of structural deterioration

Conclusion

The combined UT and visual inspection revealed the hull to be in good condition with intact plates. Some marine growth was found, but nothing that compromised vessel safety. This kind of routine inspection is vital not just for regulatory compliance but for the long-term safety, efficiency, and reliability of maritime operations. ROVs like EyeROV TUNA make such inspections safer, faster, and more data-rich, eliminating the need for divers while capturing detailed insights even in challenging underwater conditions.

Read more about EyeROV’s Ship & Port Inspections.